We are Manufacturer, Supplier, Exporter, Job work Services Provider of Sheet Metal Enclosures, AMF Panel Box Cabinets, Convention Center Floor Utility Boxes, Sheet Metal Job Work, Terminal Box Enclosures, PDU (Power Distribution Unit) Enclosures, Floor Utility Boxes, HMI (Human Machine Interfaces) Panel Cabinets, VFD (Variable Frequency Drive) Panel Enclosures and our set up is situated in Pune, Maharashtra, India.We have dedicated 5000 sq ft. fabrication setup located in Chikhali, Pune. Our setup is equipped latest technologically viable and best suited CNC machines and driven by efficient and experienced team of engineers, operators, welders, fitters and assemblers. The entire manufacturing process is aligned to obtain best use of technology and highest degree of controlled quality products and practices. We have outlined roles and responsibilities at each stage of manufacturing process to turn, on paper customer requirements into a best suited reality.

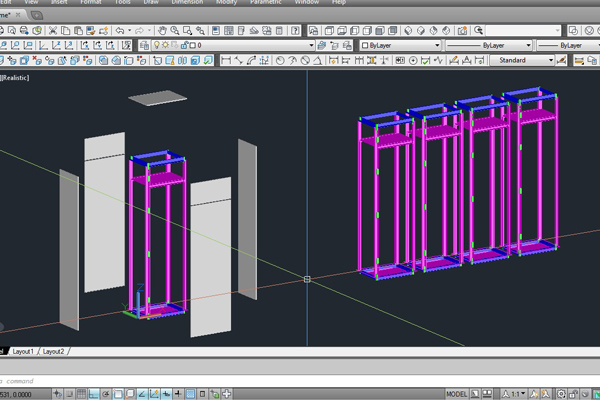

Design

Our industry experienced team of engineers crafts the customer requirement utilizing advance sheet metal software AUTOCAD & SOLID WORKS. A better design is incepted to fulfill each smaller customer requirement with high end visualization. All designs then are verified by customer and superiors before processing below the tools.

Machining

We have well established and highly modernized machines to convert raw material into accurate and precise end product. Machine shop is equipped with best in class Laser Cutting Machine, CNC Bending Machine, CNC Shearing Machine and versatile tooling to process almost every size and shape required. Experienced and technically sound work force gives a precise touch to the job with in process inspection in place, making a errorless machining process possible.

Fabrication

We have team of well experienced fitters, welders and assembler for giving shape to final product by using modernized TIG/MIG welding machines. Finishing plays a vital role how final job looks. Our finishing team ensures a smooth profile post welding and all excess burrs/spatter removed before processing the job for powder coating / assembly.

Powder Coating

Our powder coating facility ensures seven tank surface preparation to modernized oven which gives high quality of surface finish with required DFT. Automatic temperature monitored oven ensures precise and consistant curing. Overall process is monitored and ensures surface finish & adhesion test.

A dedicated quality control team ensures outlined procedures are adhered and final job excels the requirements. All in process inspections are regularized and necessarily recorded to ensure in process quality check. Quality is achieved by team efforts where each individual pays full attention towards common quality objective.